Technology is evolving quickly; particularly software development. And users expect to be able to access anything anywhere. Beyond the internet, the one big unifying force is open source software development.

At a desktop, or while mobile on a tablet or smartphone, software must work equally well and provide the same features and results. Realtime Holdings operates in this frontier and produces software and solutions for problems in new and innovative ways.

With realtime data BI in place, it can be a simple matter then to extend the reach of your ERP system into your factory or warehouse and achieve automation in areas of manufacturing, warehousing and distribution. We have created conveyor control systems and digital picking systems for inventory and fulfillment operations.

realtime data is built on a framework which makes it easy to develop additional screens, customised to suit your business and your ERP system. Typical solutions are;

- Sales order lookup screens with hyper-links to all relevant information;

- Customer details

- Sale order line item detail

- Stock on hand

- Invoice history

- Price enquiry

- Works order lookup screens

These sort of screens provide an operator with ready access to all the information they need on a regular basis, in a single location, as opposed to what a typical ERP system provides across multiple menus and screens. This is demonstarted in the “live demo” screens on this website with the extensive use of hyper-links.

We have decades of experience in the development of highly customised applications to suit individual businesses; particularly in the areas of manufacturing, warehousing and distribution. These include machine and process automation, and integration with third party applications (APIs). Some examples of this are described below.

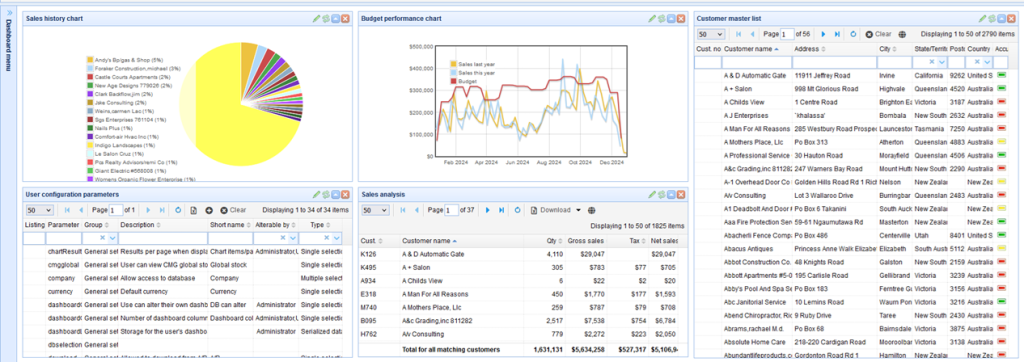

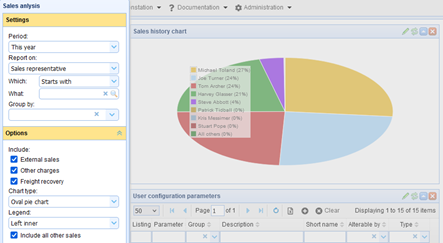

Dashboards

realtime data allows almost any screen to be added into a dashboard. A dashboard provides a view of multiple screens. There may be multiple veies, with each view containing a different arrangement of screens. Users can create and customise multiple dashboards to suit themselves, and dashboards can be created for viewing by users in particular groups. This is a standard feature of the software.

Additional customised screen can also be added into dashboards in an identical manner. This means that highly customised dashboards can be created and displayed in large “kiosk” screens throughout your business.

Users are able to create and rearrange their own dashboards, and other priveleged users are able to create dashboards and publish them to selected user groups, or as a default dashboard to be seen by all users.

Different dashboard views will have varying layouts of screens with each view. And each view may have 2 or 3 columns, or just a single colum of screens. And the settings of each screen withing each vew may be chnaged and updated directly in the dashboard.

ERP and 3rd party integration

Every ERP system is different, and the manner in which realtime data is integrated with each to extract its data is different, but the technique is generally the same. realtime data includes a “data update” scheduler which schedule tasks which will extract the raw copies of the ERP data, and then other tasks which will generate optimised versions of that data for display in the various analysis and lookup screens provider in the software. Below is a summary of various systems and how this is achieved.

iScala

iScala typically uses MSSQL as the data base, so this is very easily integrated with realtime data. But the database schema appears to retain very old naming of tables and fields which is probably a hangover from the days when it ran on simpler ISAM tables.

realtime data includes tools which simplify how any iScala table and any selection of fields in each table can be mapped into realtime data’s own SQL data base. All the standard iSacala tables and fields are defined in realtime data, along with meaningful field names to be used within realtime data’s own database, e.g. “OR20.OR20000” maps to “OrderNo” and “OR20.OR20002” maps to “CustCodeInv”.

When the tables are mapped, it is then as simple matter to create a “data update task” which will regularly extract the data from iScala in realtime data’s own MySQL database. This is typically very fast; around 30,000 records per second, so even the large sales order line item table can be updated regulary.

The data in iScala is well defined, although the obscure table and field naming makes it unintuitive. But the mapping tables provided by realtime data simplify this task and allow you to quickly identify relevant fields in the iScala database.

realtime data BI is well adapted for iScala and can be readily deployed.

Sage Accpac

Sage Accpac also uses MSSQL as the data base, so this is very easily integrated with realtime data. The table and field names are well defined and use meningful names. realtime data includes tools which allows any selection of fields in each table can be mapped into realtime data’s own SQL data base.

When the tables are mapped, it is then as simple matter to create a “data update task” which will regularly extract the data from iScala in realtime data’s own MySQL database. This is typically very fast; around 30,000 records per second, so even the large sales order line item table can be updated regulary.

realtime data BI is well adapted for Sage Accpac and can be readily deployed.

Third party systems

realtime data has also been intergated with many third party system. Every system is different and the approach which needs to be taken will vary. But the framework employed by realtime data make it relatively easy to develop these interfaces. Examples of some of the interfaces which have been created include;

- Mailchimp campaign creation using the Mailchimp API

- TGE (Toll) integration for generation of manifests, cosignments and shipping labels using their “mainfest” and “print” APIs

- MYOB and XERO invoice creation

- Fishbowl price list update using the Fishbowl API (XML)

Warehouse automation

With realtime data BI in place, it can be a simple matter then to extend the reach of your ERP system into your factory or warehouse and achieve automation in areas of manufacturing, warehousing and distribution. We have created conveyor control systems and digital picking systems for inventory and fulfillment operations.

Realtime has extensive experience with businesses in warehousing, inventory and distribution, and the system is often developed to provide facilities which extends into the factory or warehouse. This includes;

- Order picking screens

- Document printing, e.g. delivery dockets and invoices

- Address label printing

- Time recording

- Production dashboards

More complex automation has been created with direct machine interfaces as well. This includes conveyor control systems whereby finished product is delivered from manufacturing into the warehouse by way of a conveyor, whereby the product is automatically weighed and verified on the conveyor before it is delivered to the relevant section of the warehouse. This is achieved by;

- The finished product is packed into boxes which will travel on the conveyor

- A sticker is applied to the box with a unique numer encoded in a barcode.

- The finished weight of the product and the quantity in the box is known by realtime data, because it has produced the sticker.

- The box is placed on the conveyor where it will eventually will pass over a checkweigher which will capture the actual weight of the box and its barcode number.

- The box number and weight is sent from the conveyor control system to realtime data which will compare this against its record, and it will respond with by sending back a destination code or a “reject”.

- If the box is not rejected, realtime data will also instruct the ERP system to update these products into inventory.

- The conveyor control system will then direct that box, either to the nominated destination where it will be placed into inventory, or to a “reject lane” where operators will need to manually verify of correct the quantity and/or weight of the box.

The benefit of this automation is that products are automatically updated into inventory in a timely manner, and this along with the weight verification overcomes problems which would lead to inaccurate inventory in a manual system.

Digital picking trolleys

Realtime has created digital picking trolleys for one customer. This is significant development and customisation. But it is an example of what can be achieved within the realtime data framework at a fraction of the price of what a commercial solution would cost. These picking tolleys include;

- A wireless computer with a touchscreen

- A printer to print stickers locally

- A scanner for scanning shelves and product barcodes

- Shelves with lights indicating where picked items should be placed

- The computer provides audible instructions to the operator

- Large battery with enough capacity fo an entire shift

These trolleys greatly improve the accuracy and efficiency of picking orders. Multiple orders may be picked at the same time and the trolley provides visual and audible guidance to the operator. And accuracy is improved since the operator must verify the picking location and product with the scanner. The procedure is;

- The operator selects one or more orders to be picked

- When ready to proceed, the trolley will arrange all the picks so that the operator travels through the warehouse in the most efficient manner.

- The trolley will announce the location of the next pick, e.g. “Next item, row 16 bay 14 shelf 7”

- The screen will also show a map of the warehouse bay hightlight the shelves to be visited.

- When the trolley arrives at the location, the operator will scan the shelf to verify the location.

- The trolley will announce the quantity top be picked and the shelf where the items should be placed, e.g.; “OK, 5 bundles on shelf 3A”

- The operator will confirm the the items are picked on the touch screen then the trolley will announce the next location to proceed to.

- If the operator has picked more orders than can fit on the trolley, the pick will be broken up into several picking sequences. So when the trolley is full, they will unload those items and the trolley will commence on the next picking sequence.